Methyl Hydroxyethyl Cellulose MHEC

Methyl Hydroxyethyl Cellulose MHEC is a white or near-white powder or fibrous substance with good water solubility. It is obtained by chemical modification of natural cellulose,

Category:

Methyl Hydroxyethyl Cellulose MHEC

Inquiry

Product Description

1. Methyl Hydroxyethyl Cellulose MHEC is a white or near-white powder or fibrous substance with good water solubility. It is obtained by chemical modification of natural cellulose, with thickening, suspension, bonding, film formation and other functions. In cosmetic and personal care products, MHEC is primarily used as a thickener, stabilizer and film forming agent to improve the texture, stability and durability of products.

2. Performance characteristics

Thickening: MHEC can significantly improve the consistency of cosmetics and personal care products, giving them the desired texture and taste.

Stability: MHEC is highly adaptable to pH, electrolyte and temperature, and can maintain product stability under a variety of conditions.

Suspension and settlement prevention: MHEC can effectively suspend particles or pigments in the product to prevent their settlement, so that the product remains uniform for a long time.

Adhesion and film formation: MHEC has good adhesion and film formation properties, which can enhance the adhesion and durability of the product.

Low irritation: Compared to other thickeners, MHEC is less irritating and less irritating to the skin and eyes.

Biodegradability: MHEC is biodegradable and environmentally friendly.

3. The use of methods and precautions

MHEC is usually added late in the production process and can be blended directly with other ingredients. Due to its good water solubility, MHEC can be easily dissolved in water or mixed with other solvents. When using, the amount of addition should be controlled to avoid affecting the stability of the product. In addition, MHEC should be stored in a dry, cool place to avoid direct exposure to sunlight and humidity.

4. Safety evaluation

MHEC is a widely used additive in cosmetics and personal care products, and its safety has been recognized by several countries and regions. However, for certain groups of people (such as those with allergies), skin testing is recommended before use to ensure safety.

5. Production situation

The production of MHEC mainly relies on natural cellulose as raw material and is prepared by a series of chemical modification reactions. With the development of science and technology and the improvement of environmental protection requirements, more and more manufacturers have begun to use environmentally friendly production processes and raw materials to ensure the environmental performance of products. At the same time, with the growing demand for personal care products, MHEC's market size is also expanding.

6. Market prospects and development trends

With the continuous development of cosmetics and personal care industry, the application prospect of MHEC is very broad. In the next few years, the market demand for MHEC will continue to grow, and its development trend is mainly reflected in the following aspects:

New application areas continue to expand: The range of applications of MHEC in cosmetics and personal care products will be further expanded, especially in emerging areas such as facial masks, shampoos, and body washes.

Environmental protection and sustainable development: With the increase of global environmental awareness, MHEC's production will be more environmentally friendly and sustainable development, using more environmentally friendly raw materials and production processes.

Personalization and refinement: With the increase in consumer demand for personalized cosmetics and personal care products, MHEC's products will be more refined to meet the needs of different consumers.

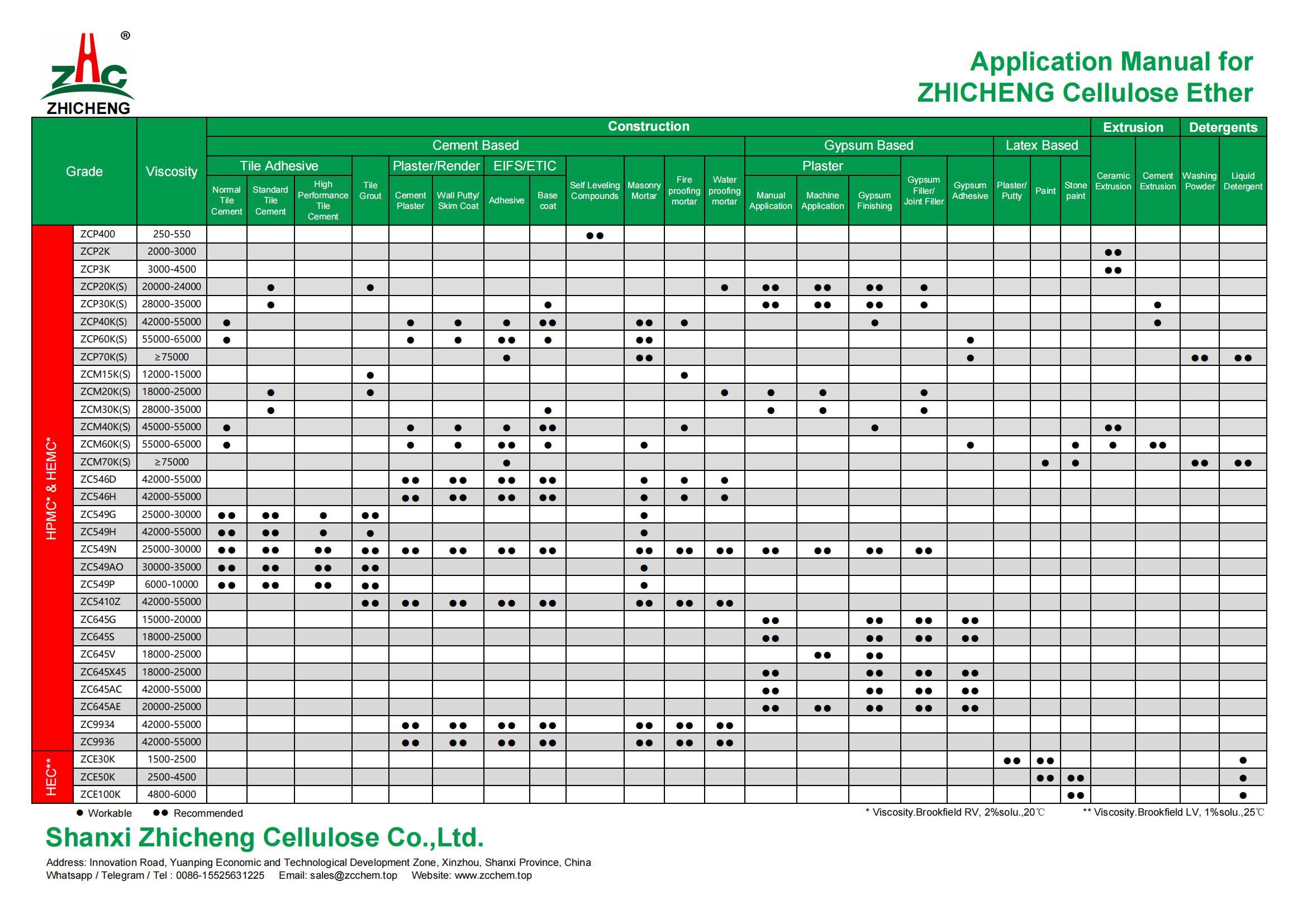

Application Manual forZHICHENG Cellulose Ether

More Information about ZHICHENG Products:

1. Products classification: ZCP grades(unmodified products with surface treatment or not) ZC grades(highly modified products)

2. Viscosity range: 50~54,000 mpa. s(Brookfield RV) or 50~200,000 mpa. s(NDJ/Brookfield LV)

3. Quality stability: ZHICHENG apply "half-done products management" which ensures the most stability of our products' quality.

4. Unmodified products: Higher purity, better performance and more stable

5. Highly modified products: Imported technology offers better properties like water retention, slip resistance, crack resistance, longer open time, etc. Widely used in Tile adhesives, Wall Putty, Mortars, Gypsum based products, etc.

6. Products traceability: We keep samples for each batch No. products for 2 years to track any quality problem raised by customers.

7. R&D center: We have a world-class R&D center to ensure the most professional technical support to our customers.

ZHICHENG New Materials is an excellent exporter of HPMC for tile adhesive, ceramic tile adhesive, tile adhesive mortar, good water retention, longer open time, slip resistance, better workability in China, which is also a professional manufacturer and supplier. Our factory has been focused on the production of high quality cellulose ethers products of industrial grade and construction grade for years. If you need such products and don't know where to buy, come and contact us. We will offer you competitive price and professional services.

ZHICHENG always aim to offer customers: The Most Cost/Effective Products.

If you are interested in our products, please contact us without hesitation.

Email:sales@zcchem.top

Previous Page

Related Products

Online Inquiry